Kui plaanite paigaldada keraamilisi plaate oma koju, olenemata kas seinale või põrandale, on soovitatav esmalt tutvuda erinevate keraamiliste plaatide lahenduste ning nende omadustega enne, kui süvenete visuaalsele poolele nagu värvus, mustrid ja viimistlus.

Mis puudutab keraamiliste plaatide välimust, siis saadaval on üsna laias valikus tõetruud disainid looduslikust kivist, marmorist, puidust, betoonist ja metallist. Keraamilised plaadid on paljudest viimistlusmaterjalidest märkimisväärselt praktilisemad, omades eeliseid nagu kõrgem vastupidavus, lihtne hooldus ning pikaajalisus. Lisaks on keraamiliste plaatide puhul märkimisväärselt lihtsam kombineerida erinevaid mõõte ja mustreid.

Keraamilised plaadid on nii ühiskondlikes kui ka eluruumides põrandakattematerjalina vastupidavuse, hoolduse ning igapäevase puhastamise osas üks parimatest valikutest.

Erinevad keraamiliste plaatide liigid.

1. Keraamilised plaadid. Keraamilised plaadid toodetakse savi, liiva, feldspati, kvartsi ja vee segust. Antud segu kuivatatakse pulbriks, pressitakse kõrge surve all ja seejärel küpsetatakse temperatuuril 1000 kuni 1300 kraadi Celsiuse järgi, sõltuvalt plaadi tüübist. Plaatide alusvärv, olgu see siis valge või punane, sõltub nende tootmisel kasutatud savist ehk kas plaadi tootmisel on kasutatud valget või punast savi.

Kuigi enamik keraamilisi plaate on mõeldud peamiselt seinakatteks nende pehmema ja poorsema olemuse tõttu, mis muudab nad vastuvõtlikuks mõranemisele, murdumisele ning plekkidele, on olemas ka vastupidavamaid põrandaplaatide lahendusi. Need on siiski mõeldud ainult siseruumides kasutamiseks, kuna nende kõrge veeimavus (üle 4%) muudab nad välistingimustes kasutamiseks ebaotstarbekaks. Keraamilised plaadid pakuvad laia valikut formaatides, värvides ja disainides ning neid on suhteliselt lihtne lõigata ja auke puurida (võrreldes portselanplaatidega). Kvaliteetsemad plaadid tehakse sageli valgest savist, mis võimaldab toota formaadilt suuremaid seinaplaate. Antud lahendused on tihti lõigatud äärtega, et oleks võimalik plaate paigaldada minimaalse vuugiga.

Tootmismeetodid

Keraamilisi plaate saab valmistada kas MONOCOTTURA või BICOTTURA meetodi abil. Monocottura meetod, mis itaalia keeles tähendab “ühekordset põletust”, on tavaliselt kasutusel põrandaplaatide jaoks ja hõlmab plaadi aluse ning glasuuri üheaegset kõrgetemperatuurilist põletamist. Ajalooliselt kasutati antud meetodit kuni 1990. aastate lõpuni enamiku eluruumide põrandaplaatide valmistamisel.

Seinaplaate iseloomustab nende lai värvide ja dekoratiivsete viimistluste valik, mis saavutatakse bicottura tootmismeetodi abil. Kuigi termin bicottura viitab kahekordsele põletusprotsessile, võivad need plaadid läbida ka rohkem kordi põletust, sõltuvalt rakendatud glasuuri kihtide arvust. Bicottura plaatide põletustemperatuurid on madalamad kui monocottura plaatidel, kuna eesmärk ei ole saavutada maksimaalset kõvadust, vaid pigem visuaalseid efekte. Plaadi põletustemperatuur on otseses seoses plaadi kõvadusega ehk mida kõrgem on temperatuur, seda kõvem tuleb ka plaat.

2. Portselanplaadid (tihti eesti keelses kasutuses täismassplaadid).

Portselanplaate ehk täismassplaate valmistatakse peenest savist, mis on segatud kvartsi ja päevakiviga ning põletatakse ca 1300°C juures. Kõrge ahjutemperatuur muudab savi olemust, muutes selle väga kõvaks materjaliks. Portselan on peaaegu poorideta ja vastupidav kriimustustele ning võimalike plekkide tekkele. Tänu kõrgele tihedusele on portselanplaatide veeimavus vähem kui 0,5%, mis on välistingimustes kasutamiseks oluline omadus.

Portselanplaadid on suurepärane valik suure käidavusega alades kasutamiseks. Samuti on portselanplaadid ideaalne lahendus köögipõrandal kasutamiseks, kuna need ei vaja lisanduvat kaitset võimalike plekkide vastu ning on üsna lihtsalt puhastatav materjal. Enamik portselanplaate on paksusega 8 kuni 11,5 mm, kuid on olemas ka uudsed õhemad elastsed plaadid, mis võivad olla vaid 3 mm paksused. Antud õhukeste plaatide peamine eelis peitub paigalduse lihtsuses. Antud plaate saab kiiresti paigaldada olemasolevate plaatide peale ilma, et peaks algsed plaadid üles võtma, jäädes ära aega nõudev ja tolmune lammutustöö. Antud plaate on väga lihtne lõigata ja puurida. 3 mm paksus tagab ka väiksema ökoloogilise jalajälje, kuna tootmisel kasutatakse vaid ca kolmandikku tavalise plaadi materjalist.

Portselanplaatide tootmise uudse kõrge resolutsiooniga digitaalse ink-jet printimistehnoloogia abil on võimalik toota plaate, mis on naturaalse kivi või puidu välimusele äravahetamiseni sarnased. Ink-jet tehnoloogia saab suurepäraselt hakkama ka tekstuursete pindade loomisega. Antud tehnoloogiat saab kasutada ka erinevat stiili mustrite tootmiseks.

Glasuuritud ja glasuurimata portselanplaatide erinevus

Üldiselt saab portselanplaate liigitada viimistluse poolest kahte rühma: glasuuritud ja glasuurimata plaadid.

Glasuurimata portselanplaadid ehk läbimassplaadid.

Glasuurimata portselanplaate toodetakse erinevate toorainete kooslusest, sealhulgas savist, kvartsist, ränidioksiidist ja päevakivist, mis põletamisel moodustavad plaati läbiva tooni ning omadustega portselanplaadi. Tulemuseks on läbimassplaat, millel on seda läbiv looduskivi disain ilma glasuurita selle pinnal. Glasuurimata läbimassplaadi disain on läbiv kogu plaadi ulatuses plaadi pinnalt kuni põhjani välja. Lisaks disainile on ka plaadi tehnilised omadused, nagu veeimavus, külmakindlus ja happelisusele vastupidavus, kogu plaadi ulatuses samad. Minevikus olid antud lahenduse disainid piiratud, aga uued kõrge resolutsiooniga printimise tehnoloogiad võimaldavad toota keerukaid disaine samuti glasuurimata läbimassplaatidele

Pildil ABK Sensi 900 Carrara Soft antique uudse 3D tehnoloogiaga

Keraamilised plaadid ABK Sensi 900

Poleeritud glasuurimata läbimassplaat

Poleeritud läbimassplaat on läikiva pinnaga portselanplaat, millel puudub glasuur. Tegu on glasuurimata plaadiga, mis on mehaaniliselt poleeritud läikega, analoogselt nagu seda tehakse looduslikust marmorist või graniidist plaatide puhul. Ja nagu poleeritud marmor- või graniidiplaadid vajavad impregneerimist, et vältida võimalike plekkide tekkimist, nii vajab seda ka poleeritud läbimassplaat. Läbimassplaati poleerides muutub selle imavusaste. Kergelt tekstuurse naturaalse/mati pinnaga portselan ei ima endasse mustust ning plekid sellele ei teki. Mehaaniline poleerimine muudab läbimassplaadi pinna siledaks ning avab plaadi mikropoorid, muutes plaadi pinna poorsemaks ja tõenäosus plekkide tekkeks tõuseb. Antud asjaolu tõttu nõuab läbimassplaat impregneerimist (seda tehakse küll tootja poolt juba tehases). Arvestama peab ka asjaoluga, et poleerimine muudab plaadi pinna märjana üsna libedaks. Poleeritud läbimassplaadi impregneerimine lahendab küll plekkide, kuid mitte märja plaadi libeduse probleemi. Seetõttu soovitatakse poleeritud läbimassplaati kasutada põrandakattena aladel, kus on vähe või üldse ei esine võimalust plaadil märjaks saada, või siis seinakattena, mille puhul ei esine libedusega seonduvaid probleeme. Mattviimistlusega plaadid on libisemiskindlad, kuid on soovitatav kontrollida tootjapoolset libastuskindluse reitingut.

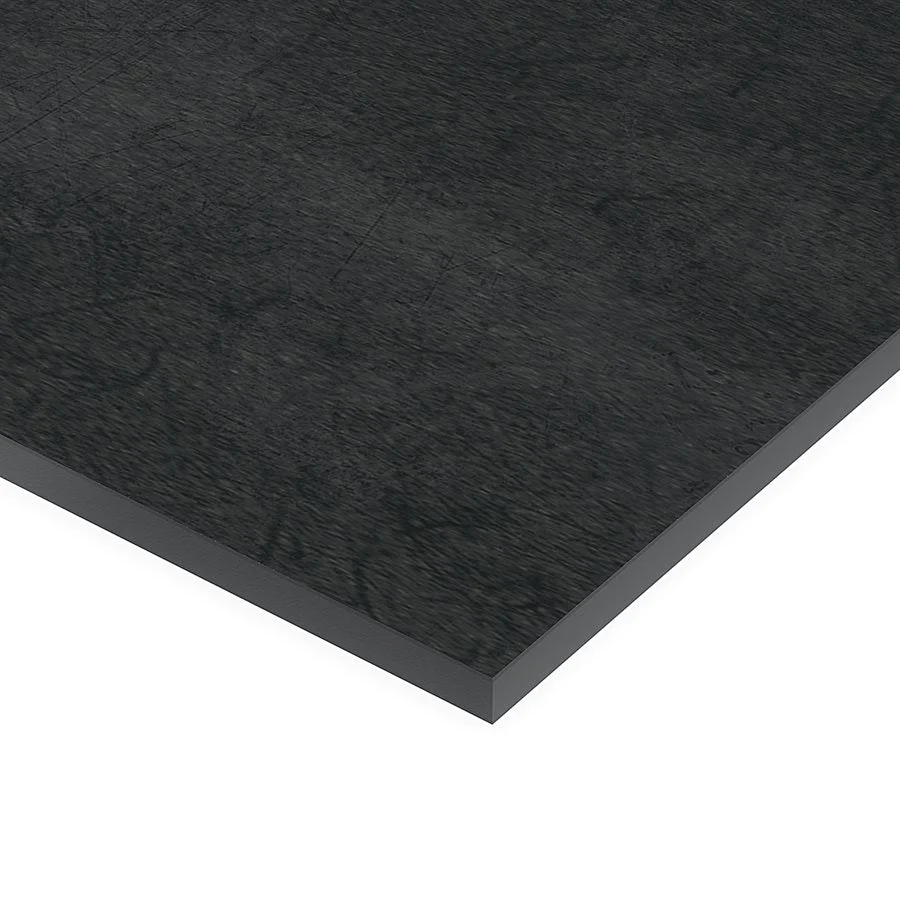

Pildil ABK Sensi 900 Precious Black poleeritud glasuurimata läbimassplaadid 120x120cm

Lappato ehk poolpoleeritud läbimassplaadid

Lappato plaadid on poolpoleeritud viimistlusega läbimassplaadid, mille läikeaste on matist plaadist kõrgem, kuid traditsioonilisest poleeritud läbimassplaadist madalam. Lappato on itaaliakeelne sõna, mis tähendab “poolpoleeritud”. See tähendab tehnikat, mille puhul plaadi kergelt struktuurne pind poleeritakse umbes 0,1 mm ulatuses selle pealispinnast ehk nö plaadi struktuuri tipud. Plaadi pind jääb kõrgemale ulatuvalt osa ulatuses poleeritud ja madalam osa on mati pinnaga ning sellest tulenevalt tekib läike ning mati pinna vaheline mäng olenevalt vaatenurgast. Vaatenurga muutudes pind kas läikega sillerdab või muutub matiks. Seega on Lappato plaatidele iseloomulik kaunis üleminek läikivatelt aladelt matile. Lappato viimistlusega plaate ei ole vaja impregneerida. Glasuurimata portselan, lappato ehk kergelt poleeritud viimistlusega, omab libisemiskindluse reitingut kusagil poleeritud ja mati vahel.

Pildil ABK Alpes Raw Lead lappato poolpoleeritud 60x120cm keraamilised plaadid.

Glasuuritud portselanplaadid

Glasuuritud portselanplaatide puhul lisatakse plaadi pinnale enne selle põletamist glasuuri kiht, millest tulenevalt nimetatakse antud plaate ka “glasuuritud portselanplaatideks”. Glasuuritud pinda luuakse tootmisprotsessi käigus, lisades vedelat klaasi plaadi savist kehale enne selle põletamisprotsessi. Hoolimata asjaolust, et tootmisel lisatakse plaadi pinnale vedelat klaasi, ei ole glasuuritud portselanplaatide pind ainult läikiv. Glasuuritud portselanplaatidel võib olla läikiv, matt, lappato või tekstureerne. Kuna tooni viimistletakse vaid plaadi pealmine kiht, on antud plaatide tootmisprotsess pisut soodsam. Antud asjaolu muudab need plaadid tarbija jaoks pisut soodsamaks ja atraktiivsemaks lahenduseks.

Pildil põrandal ja tausta seinal TAU Belcastel 90x180cm ja paremal seinal TAU Corten 60x120cm keraamilised plaadid.

Lisaks viimistlusele liigitatakse portselanplaate veel nelja gruppi konstruktsiooni järgi.

Portselanplaate on saadaval järgmist tüüpi: läbimassplaat, toonitud alusega portselanplaat, kahekihiline portselanplaat ning valgel ehk toonimata alusel portselanplaat.

Läbimassplaadid ehk Full body tiles

Läbimassplaadid on plaadid, mille pinnadisain ja toon on plaadi keha/ristlõiget/paksust läbiv. Läbimassplaadid on ideaalsed kasutamiseks keskmise kuni kõrge koormusega ühiskondlikel ning ka kodustel pindadel. Läbimassplaat on parim lahendus suure koormusega kaubanduslikes, avalikes ja tööstuslikes piirkondades. Läbimassplaate kasutatakse kauplustes, koolides, lennujaamades ning 2–3 cm paksuseid lahendusi avalikel kõnniteedel, ühistranspordi platvormidel jne. Pindadel, kus on vaja eriti kõrget vastupidavust ja kulumiskindlust, on läbimassplaadid parim valik. Koduses kasutuses sobib läbimassplaat sisuliselt igale poole – ideaalselt sobiv eluruumidesse, kööki, koridoridesse, terrassidele, töötasapindadele ning ka vannitubadesse, nii põrandatele kui ka seina. Paksemad 2 cm lahendused sobivad välitingimustes terrasside, käiguteede jne katmiseks. Läbimassplaate võib pidada üheks kõige vastupidavamaks põrandakattematerjali liigiks. Võrreldes näiteks loodusliku graniidiga on läbimassplaadid looduslikust graniidist umbes kaks korda kõvemad. Kuna läbimassplaatidel on plaati läbiv disain ja toon sama, on nad eriti kulumisele vastupidavad ja pikaealised. Tehnilised omadused nagu vastupidavus, veeimavus ja tihedus on lisaks disainile ja värvusele samuti plaati läbivalt ühtlased. Meie läbimassplaatide valikus on esindatud hulk disaine ja laias valikus mõõtudega Itaalia firmalt ABK Ceramiche. ABK Ceramiche pakub head kvaliteeti ja innovaatilisi lahendusi mõistliku hinnatasemega.

Toonitud alusega portselanplaadid ehk Full Colored Body Porcelain Tiles

Toonitud alusel portselanplaadid viitavad lahendusele, mille puhul plaadi alus/keha/kook on toonitud läbi kogu plaadi ristlõike/paksuse samasse tooni. Värvipigmendid lisatakse plaadisegule, et tagada plaadi keha värvuse vastavus analoogselt plaadi pinnaga. Küll pole antud lahenduse puhul plaadi aluses olev disain pinnal oleva disainiga analoogne. Toonitud alusega portselanplaat pakub võrreldes toonimata alusega portselanplaadiga lisanduvat kindlust juhul, kui peaks juhtuma harva esinev glasuuritud pinna kahjustus/mõranemine või eriti suurest koormusest tingitud kulumine. Antud juhul pole kahjustused/kulumine silma riivavad, kuna plaadi aluskonstruktsioon on plaadi pinnaga samas toonis. Antud asjaolu muudab toonitud alusega portselanplaadid sobilikuks keskmise koormusega ühiskondlikele aladele, nagu kaubanduspinnad, kontorid jne. Kodutingimustes sobib sisuliselt igale poole.

Kahekihilised portselanplaadid ehk Double Loaded Porcelain Tiles

Kahekihilised portselanplaadid koosnevad kahest üksteisest selgesti eristuvast kihist – pealmine, läbimassist koosnev, umbes 3 mm paksune viimistluse kiht ning plaadi aluskiht, mis koosneb tavalisest toonimata portselanist, mis on toonilt ja viimistluselt selgesti eristatav. Need kaks kihti pressitakse omavahel kõrge surve all kokku. Pärast pressimist kuumutatakse plaate ahjus kõrge kuumusega, moodustades ühtse plaadi, mille ülemine kiht hoiab ära pinnakahjustuste tekkimise, mis võiks paljastada aluskihi, pakkudes seeläbi esmaklassilisi disaine läbimassplaatidest soodsama hinnataseme juures. Antud lahendus on hea, kuna võimalikud kriimud või kerge kulumine ei paljasta aluskihi erinevat tooni, samas on antud lahenduse hind märkimisväärselt madalam võrreldes läbimassplaadi hinnaga. See muudab kahekihilised portselanplaadid väga sobilikuks ühiskondlikele aladele, mis saavad tavapärasest kõrgemat koormust, nagu fuajeed, ostukeskused jne.

Toonimata alusega portselanplaadid ehk Off-White Body Porcelain Tiles

Toonimata alusega portselanplaadid viitavad lahendusele, kus disain ja värv on ainult plaadi pinnal, samas kui ülejäänud plaadi ristlõige/paksus koosneb toonimata ja heledast portselanist. Tegu on analoogselt toonitud alusega plaatidega glasuuritud pinnaga lahendusega. Antud lahendusega saab luua unikaalseid ja ilusaid disaine, mida kaitseb glasuuri kiht, tagades plaatide vastupidavuse kulumisele. Glasuuritud plaatide vastupidavust saab kontrollida PEI (Porcelain Enamel Institute) reitingu järgi. Kuigi toonimata alusega portselanplaatide konstruktsioon on sama vastupidav ja külmakindel kui ülejäänud portselanplaatide tüüpide puhul, sobivad nad paigaldamiseks aladele, kus on oodata kerget kuni mõõdukat ühiskondlikku koormust, aladele, kuhu tekib vähem abrasiivset mustust. Neid sobib kasutada ka kergetes kaubanduspiirkondades, nagu kontori vastuvõtualad, kuid mitte suure liiklusega aladel, nagu kaubanduskeskuste sissepääsud jne. Kodutingimustes võib neid kasutada nagu teisigi portselanplaate pea kõikjal – eluruumides, esikutes, köökides, magamistubades, koridorides, rõdudel, taustseintel, töötasapindadel ja vannitubades, nii põrandatel kui ka seintel.

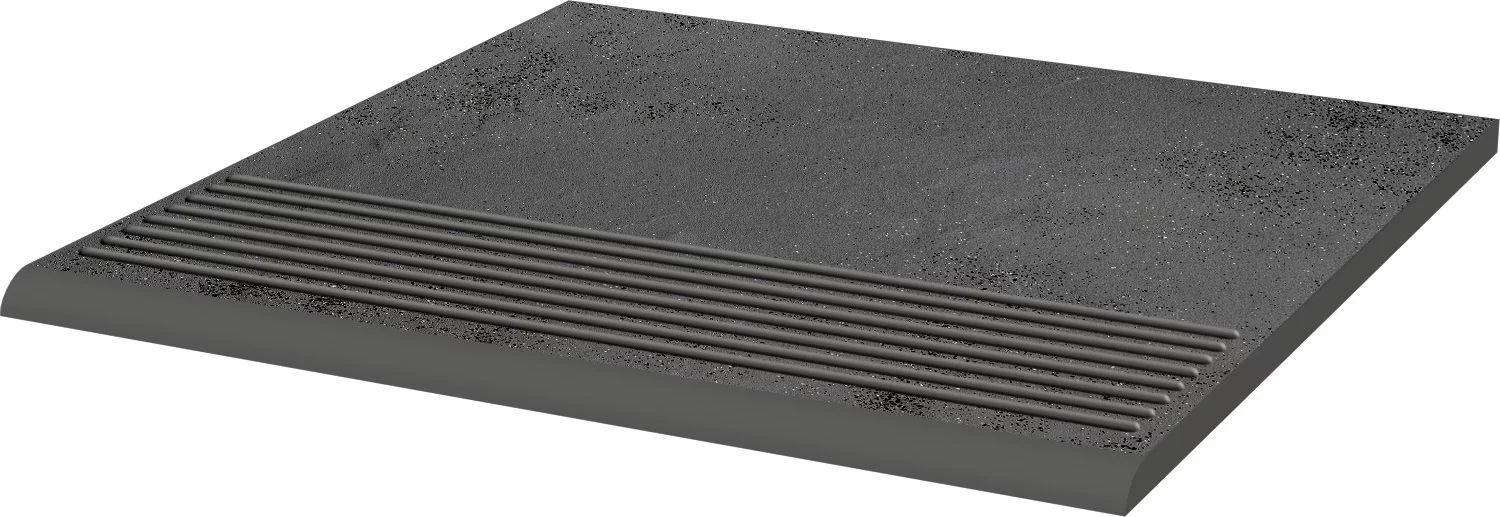

3. Klinkerplaadid

Klinkerplaate valmistatakse savist ja erinevatest mineraalidest, mis surutakse kokku kõrge rõhu all ja küpsetatakse seejärel temperatuuril umbes 1000–1100 °C. Küpsetusprotsessis muutuvad plaadis olevad rauaosakesed hematiidiks, andes plaatidele loomulikul moel iseloomuliku punase või punakaspruuni värvuse. Tänapäeval on saadaval lisaks punakale või punakaspruunile ka halle jne. toone, mida saavutatakse, lisades värvipigmente. Klinkerplaadid on oma olemuselt tihedad, taluvad hästi külma ja nende plaatide veeimavus jääb alla 2%. Antud plaadid on väga hea lahendus välitingimustes kasutamiseks, kuna enamus tootjate seeriad omavad ka struktuurseid plaadi sisse pressitud libisemiskindlaid lahendusi, astmete tarbeks profiile, nurgaelemente jne.